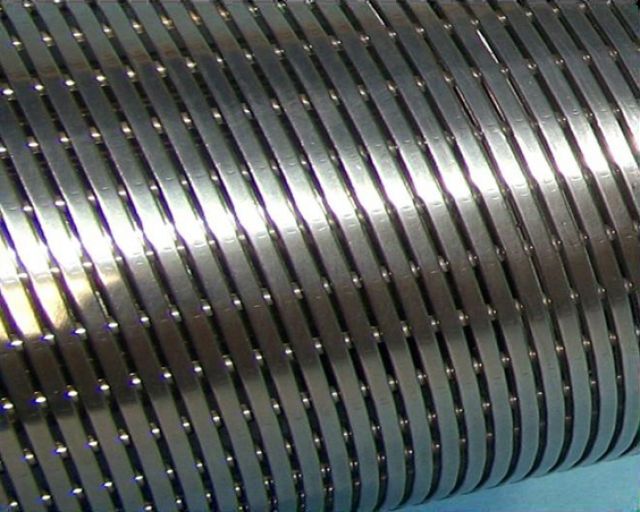

Roscoe Moss Sahara produces Continuous wire wrap screen. These screens are manufactured by wrapping and resistance welding a shaped wire around an internal array of longitudinal rods. This process lends itself to close tolerances required for very fine aperture sizes; the V-shaped slot configuration minimizes clogging by formation or filter pack particles. Continuous slot screens are usually produced from stainless steel 304L or 316L in order to avoid problems associated with corrosion of carbon steel screens.

Wire wrap screen can be designed for highly permeable small or big sand grained aquifer. CWW are very effective in wells of this type since they can be manufactured with wide range of slot opening size. And yet maintain the necessary open area to minimize any frictional head loss and enhance the well production.

Wire wrap screen can be designed for different screen diameters, collapse strengths, tensile strength, slot sizes and different lengths, different end fittings to suit your connections in terms of size and thread type. Either pin / box connection or pin / pin and full coupling collar, with API 8rd thread or Buttress thread.

- Screen different diameters, 4”, 5 5/8”, 6 5/8”, 7”, 8 5/8”, 9 5/8”, 10 3/4”, 11 3/4”, 12 3/4” , 14”

- It can be fabricated from stainless steel 304L, 316L, and galvanized steel.

- Slot size range from 0.15 mm, 0.25 mm, 0.35 mm, 0.5 mm …… 1mm….1.5 mm….

- Collapse pressure from 150 psi, …450 psi… 850 psi …1000 psi and up to 3000 psi

- Well Depth from 0 to 3000 meters

- Tensile strength range from 13 tons up to 60 tons

- Opening area up to 30 %

- Screen end fittings can be threaded or welded connection.

- Screen length is up to 6 meters.

RMS Screen prices are very competitive with the market prices. RMS can produce one well requirement in one day.