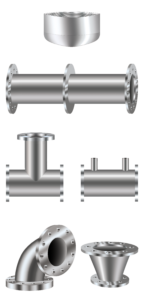

Roscoe Moss Sahara RMS is engaged in supplying and manufacturing flanges,threaded connection and pipe fittings. RMS is fully equipped with five lathe machines, ring rollingmachine, hydraulic press machine and fourteen drilling machines for the making of flanges at maximum diameter of 1800 MM (70 inch) with different classes and standards, RMS also cut APIthread different diameters with different thread type, and make various fitting products of special sizes. RMS is specialized in welding the stainless steel material with the latest technology using tri-mix gas, (Helium, Argon and CO2) to buttwelded pipe fittings, neck flange, slip on flange, blind flange, plate flange, socket welding flange, elbow, equal and reducing tee, concentric and eccentric reducer and cap. These products are welded according to AWS 1.6D standard and according to international standards as ANSI(ASME), DIN, JIS, BS, GOST, EN1092, AWWA, SABS. We can also make non-standard, special-designed items according to customers’ requirements . The materials we supply are carbon steel, stainless steel of different grades. To ensure product quality. we take rigid quality control measures according to certification from API 5CT and ISO 9001-2015 at every level of our operation. Raw material is tested and marked for stock cutting; samples are taken from batch for chemical composition analysis, hydrostatic test and function test; every finished product goes through visual and dimensional inspection before warehousing . Fine quality, competitive price, timely delivery, good reputation and years of experience in this field have well established us as reliable supplier to customers from countries over the world, including Egypt, Sudan, Libya, Tunisia, Algeria, Eretria, Ethiopia and Qatar.

Roscoe Moss Sahara RMS is engaged in supplying and manufacturing flanges,threaded connection and pipe fittings. RMS is fully equipped with five lathe machines, ring rollingmachine, hydraulic press machine and fourteen drilling machines for the making of flanges at maximum diameter of 1800 MM (70 inch) with different classes and standards, RMS also cut APIthread different diameters with different thread type, and make various fitting products of special sizes. RMS is specialized in welding the stainless steel material with the latest technology using tri-mix gas, (Helium, Argon and CO2) to buttwelded pipe fittings, neck flange, slip on flange, blind flange, plate flange, socket welding flange, elbow, equal and reducing tee, concentric and eccentric reducer and cap. These products are welded according to AWS 1.6D standard and according to international standards as ANSI(ASME), DIN, JIS, BS, GOST, EN1092, AWWA, SABS. We can also make non-standard, special-designed items according to customers’ requirements . The materials we supply are carbon steel, stainless steel of different grades. To ensure product quality. we take rigid quality control measures according to certification from API 5CT and ISO 9001-2015 at every level of our operation. Raw material is tested and marked for stock cutting; samples are taken from batch for chemical composition analysis, hydrostatic test and function test; every finished product goes through visual and dimensional inspection before warehousing . Fine quality, competitive price, timely delivery, good reputation and years of experience in this field have well established us as reliable supplier to customers from countries over the world, including Egypt, Sudan, Libya, Tunisia, Algeria, Eretria, Ethiopia and Qatar.