Liner Hanger , a device used to attach or hang a liner from the internal wall of a previously set casing string. Conventional liner hangers are “hung” (connected to the last casing) by setting slips that grip against the inner wall of the previously set casing string. Expandable liner hangers are hung by the external expansion of the hanger against the inner wall of the previously set casing string.

| (Liner x Casing), in | O.D of Casing, in | Weight Range, Ib/Ft | Top Connection |

| (20 x 13 3/8 , 9 5/8 & 8 5/8) | 20 | 94 – 133 | 13 3/8 “ACME L.H.T” Box |

| (18 x 13 3/8 , 9 5/8 & 8 5/8) | 18 | 94.5 – 106 | 13 3/8 “ACME L.H.T” Box |

| ( 13 3/8 x 9 5/8, 8 5/8, 7 & 6 5/8) | 13 3/8 | 54.5 – 68 | 9 5/8 “ACME L.H.T” Box |

| (9 5/8 x 7 & 6 5/8) | 9 5/8 | 36 – 47 | 6 5/8 “ACME L.H.T” Box |

| (7 x 4 1/2) | 7 | 23 – 32 | 4 1/2 “ACME L.H.T” Box |

| Free Movement Setting Tool | —- | —- | 4 1/2 “, 3 1/2” & 2 7/8Box |

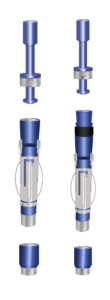

Mechanical set Liner hanger

Mechanical set Liner hanger

RMS mechanical Set liner hanger is designed for use in wells for hanging casing or screens on previous casing, where the work string can be manipulated to set the hanger slips.The liner hanger is composed of the hanger body with cone shape on the top sections, rubber packer (Optional), slips and a cage assembly to carry the slips. The cage contains a (J) slot and drag spring centralizer, When the liner hanger reaches the target depth, mechanical manipulation of the hanger body moves the cage (J) slot from the running position to setting position, bringing the slips into contact with the cone, to anchor the slips to the outer casing and inflate the rubber element to isolate the annulus. Special running tool (Free movement tool) allow losing the weight of the liner once it anchors, indication for setting, then the square shape of the running tool allow to disconnect by using the left hand ACME thread

Roscoe Moss Sahara Hydraulic setting liner Hangers

Roscoe Moss Sahara Hydraulic setting liner Hangers