Roscoe Moss Sahara as a subsidiary of Roscoe Moss Manufacturing, RMS is in charge of marketing all RMC products such as shutter screen and spiral welded casing. RMS maintains stock of RMC products and it is subject for availability at the moment of the order.

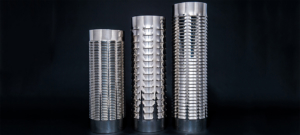

Shutter screen

It is also known as louver screen, is manufactured by forming downward facing louver shaped openings into pipe up to 40 feet long. The process incorporates the use of an internal mandrel which perforates the shutter against external blocks. Shutter screen is commonly produced from a variety of steel types including carbon, copper-bearing, high-strength low-alloy, and stainless. This type of screen is particularly suited for use in large diameter, deep, gravel envelope wells. In many parts of the world, wells of this type of pumping ground water from thick formations consisting of sands and gravels. Shutter screen is the product of choice for these wells because it is hydraulically efficient, strong and durable. The smooth, unobstructed interior of shutter screen allows the efficient use of highly effective development techniques such as swabbing and also facilitates the employment of efficient maintenance and repair methods. Disadvantages of shutter screen include unavailability of slot size smaller than 0.040″; its limited open area also restricts its use in thin highly prolific aquifers. Development techniques such as jetting (highly effective in naturally developed wells but ineffective in gravel envelope wells) may not be used as efficiently through shutter screen.